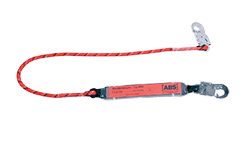

Fall Arrest PPE

You simply cannot do without it: In a workplace where the risk of falling has not yet been eliminated through collective protection measures, the use of personal fall protection equipment is absolutely vital. Please find in our PPE range guided type fall arresters, self-retracting lifelines, safety harnesses and more.

Product filter

Filter

- Product filterProducts found

- Certification

- Max. no. of users

- Application

- Expand selection