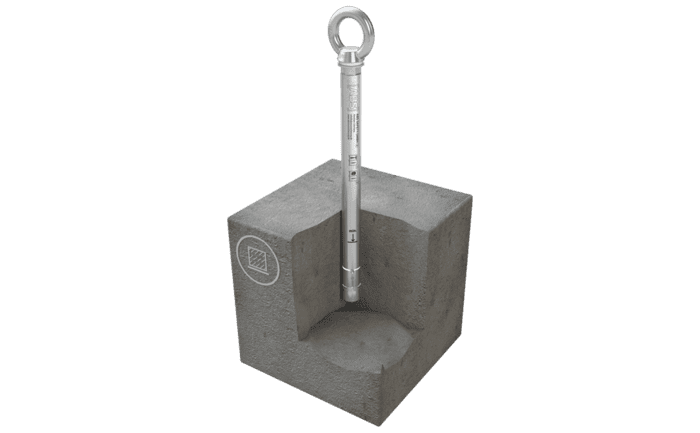

Find out more about our ABS-Lock III-BE Pro-24 Easy-to-handle and ETA approved anchorage point for concrete installations, including an integrated inspection feature

Using an ABS-Lock III-BE Pro-24, installing an individual fall arrest solution and taking care of your annual inspections is child’s play: To permanently install the device, all you need is one single bore hole drilled into the concrete surface of your flat roof. The special dowel at the bottom of the support opens up simply by tightening the nut at the top with any standard torque wrench (170 Nm).

Our high-quality, stainless steel ABS-Lock III-BE Pro-24, which was developed in Germany, takes a load of work off your shoulders and also makes it much easier for specialists to carry out your mandatory annual inspections: Simply by tightening up the nut, which is located above the seal so it is always readily accessible, a specialist can easily test whether the anchor is still firmly installed in the subsurface.

Installing one of these modern anchorage devices only takes a couple of minutes. Simply drill a hole and hammer the rod in up to the mark using the practical percussion drill bit. In just a few seconds, the anchor is firmly installed and can be used immediately for attaching personal fall protection equipment (PPE) . As usual, all the required master data for your installation documentation and annual inspections can be found on the anchorage point - laser-etched to resist adverse weather conditions. Your days of battling against weather-worn labels are over.

In addition to using our ABS-Lock III-BE Pro-24 as an individual anchorage point for securing individuals, it is also ideal for installing a rail or lifeline system - thanks to its robust rod. In this case, the components required for your individual safety system are simply attached to the top of the stainless steel rod - replacing the anchorage eyelet. Combine this, for example, with an ABS Lock SYS system to set up a lifeline system.