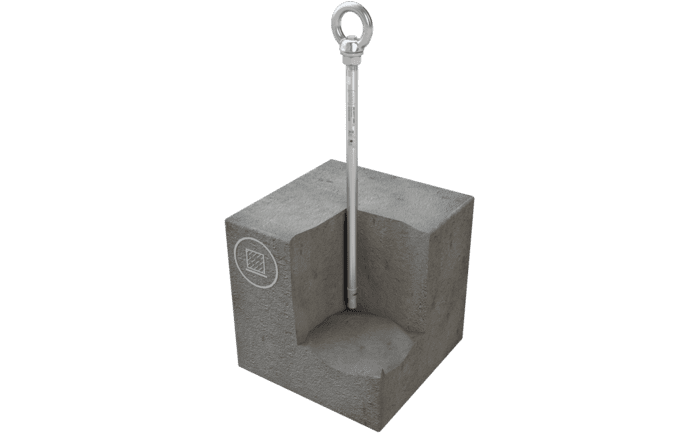

Find out more about our ABS-Lock III-BE Pro Drill, hammer, torque: Easy-to-install, ETA-approved anchorage point for concrete surfaces

Simply hammer it in, expand the dowel and you are ready to go. Our ABS-Lock III-BE Pro anchorage point for individuals makes installing a fall protection solution on a flat roof even easier. This is because all you need to install it on a concrete surface is just one bore hole. Our stainless steel anchor is equipped with a specially-designed dowel which is expanded in one easy step. All you require to do this is a torque wrench.

Of course, you can also use our anchorage device, which has been awarded European Technical Approval (ETA-20/0602), as an intermediate post in a lifeline system.

Like its predecessor, installing an ABS-Lock III-BE Pro only requires one single, carefully brushed out, bore hole. The device’s unique feature, however, is that the dowel at the bottom can be expanded from the top using a torque wrench. This totally rules out any uncertainty about how to install it. The installation technician can see straight away that the anchor is firmly in place!

It is also just as easy to check how firmly the anchor is embedded in the subsurface - at any time you want, without the need for complicated pull-out testing and with conclusive results. This is due to the fact that the method of accessing the dowel using a torque wrench is still open to you even after the device has been installed - not only making the required annual inspections child's play but also providing much better information on the status than that obtained through a visual inspection alone.