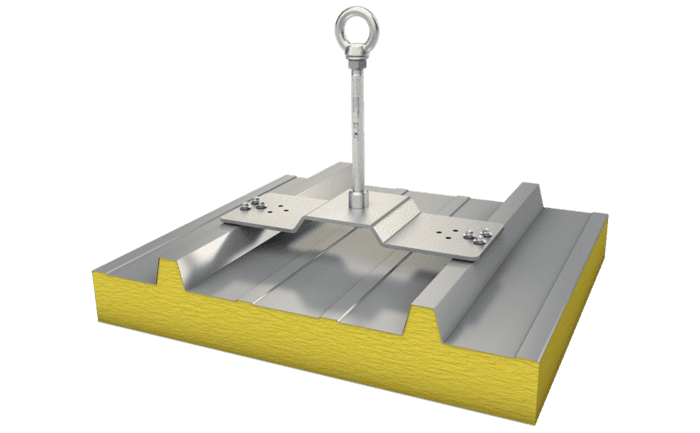

Find out more about our ABS-Lock X-SW-6 Simply screwed into place: Anchorage device for sandwich roofs

Our weather-resistant ABS-Lock X-SW-6 anchor scores extra points through being really easy to install from above. The anchorage point base plate is attached to two seams - directly over the wooden beams or Z purlins - using 6 screws. These screws are simply inserted through the sheeting and installation layer into the load-bearing substructure below. Of course, we also supply the screws in the length you need according to your specifications.

This robust, stainless steel anchorage point is capable of securing 3 roof workers simultaneously once it has been correctly installed. All your roof workers, carpenters & Co. need to do is to simply hook up the connectors of their personal fall protection equipment (PPE) to the anchorage eyelet of our ABS-Lock X-SW-6. This anchor can either be deployed as a retention system or as an arresting system. All the important product specifications have been laser-etched into the supporting rod so that they can be easily read.

To make sure that our ABS-Lock X-SW-6 anchorage point can be installed on sandwich profiles with different seam intervals, we have drilled a variety of holes into the base plate (distance between the holes 250 mm / 333 mm). The product comes with self-adhesive sealant patches and installation materials. When selecting stainless steel bolts to match, please contact our Sales & Engineering Team and make sure to let us know the depth of your sandwich elements and the nature of the supporting substructure.

This anchorage point can also be easily converted to support an intermediate bracket, corner element or end terminal (with a tensioning element) in a lifeline system. Our product range includes all the components you need to set up an ABS-Lock SYS system.